-

HOME

-

ABOUT

-

PRODUCTS

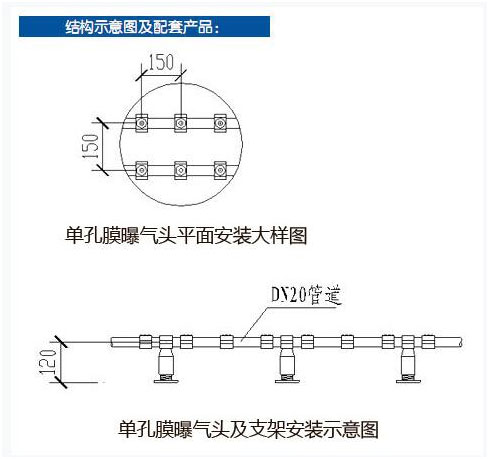

Flat aeratorSingle pore membrane aerator Tube Aerator Rotary mixing aeratorCyclone aeratorDisc type microporous aeratorVibration aerator170 Mixing aeratorTPU aeration tubeOblique pipe packingMBBR biological fillerBraided filling materialCombined packingPolyurethane sponge fillerHollow sphere packingSuspended ball packing materiaElastic filler

Flat aeratorSingle pore membrane aerator Tube Aerator Rotary mixing aeratorCyclone aeratorDisc type microporous aeratorVibration aerator170 Mixing aeratorTPU aeration tubeOblique pipe packingMBBR biological fillerBraided filling materialCombined packingPolyurethane sponge fillerHollow sphere packingSuspended ball packing materiaElastic filler -

CASES

-

NEWS

-

CONTACT

.jpg)

.jpg)