Accessories Description: 1 plug, 2 stainless steel clamps, 3 aerator body, 4 aerator micropores, 5 connectors, 6 gaskets I, 7 gaskets II, 8 center pipes, 9 distribution pipes, 10 bending plates

structure

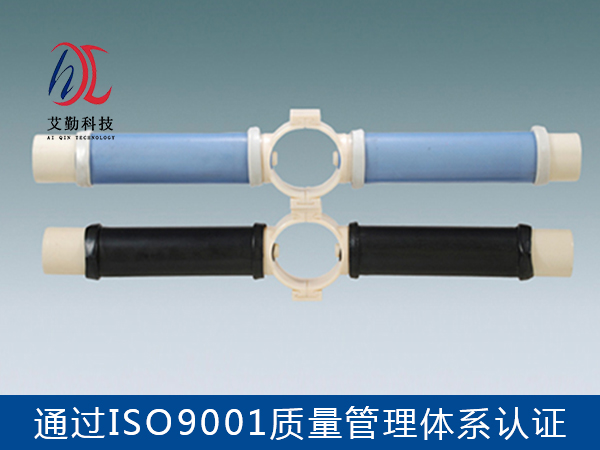

Aeration membrane, support tube, air pipeline. The outer diameter of the tubular aerator is 69mm, with conventional sizes of 580mm, 800mm, and 1000mm. For lengths below 580mm, extrusion or compression molding is used, while for lengths greater than 580mm, extrusion molding is used. Drill holes on the membrane tube with a size of 1.5mm and a spacing of 2 × 2.5mm, which can generate uniform small bubbles with a diameter of 1-3mm. There is a 15mm long non porous area at the top of the membrane tube. When the gas supply is interrupted, the membrane immediately returns to its original state. Automatically prevent backflow at the air inlet.

material

1. The rubber membrane adopts EPDM rubber, which has the characteristics of heat resistance, ozone resistance, acid and alkali resistance, and good chemical stability. Compared with general rubber membranes, it can greatly improve its service life.

2. The aeration hole is a straight shaped long hole, which has good stretchability and instantaneous closure. During aeration, it can release microbubbles with a diameter of less than 3mm to achieve high oxygen utilization efficiency, with an oxygen utilization efficiency of 35-42%.

3. The support pipe is made of ABS or PVC material.

4. The air duct is made of engineering plastic ABS material and adopts a hollow and water filled form, greatly reducing the buoyancy of the aeration system in water.